ANILOX COATER MODULE

ANILOX COATER MODULE Specification

- Type

- Anilox Coater Module

- Material

- Mild Steel

- Capacity

- Depends on application

- Printing Speed

- Up to 250 m/min

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Anilox Roller

- Print Direction

- Unidirectional

- Ink Type

- Water based / Solvent based

- Color Management

- Precise

- Control System

- PLC Controlled

- Working Temperature

- 10C - 55C

- Power

- 1.5 kW - 3 kW

- Size

- Customizable

- Width

- 450 mm - 1800 mm

- Weight (kg)

- Approx 450-1200 kg (Depending on size)

- Dimension (L*W*H)

- As per customer specification

- Application

- Film, Paper, Foil, Labels, Flexible Packaging

- Safety Features

- Overload Protection, Emergency Stop

- Drying System Compatibility

- IR/Hot Air/UV

- Roller Type

- Ceramic/Chrome Plated Anilox Roller

- Web Handling

- Precision Web Guide System

- Doctor Blade System

- Chambered, Pneumatic or Mechanical

- Drive System

- Servo Motor Driven

- Installation

- Onsite Support Available

- Surface Finish

- Powder Coated/Corrosion Resistant

- Maintenance

- Easy Access Design

- Coating Thickness

- Adjustable from 2-50 microns

- Noise Level

- Below 80 dB

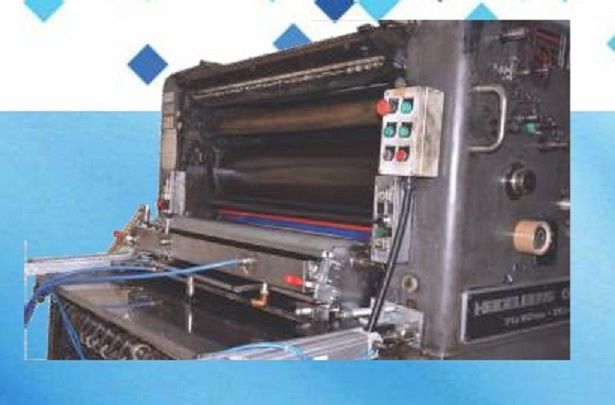

About ANILOX COATER MODULE

Experience a formidable edge in coating technology with the ANILOX COATER MODULE, now available at a price cut and the lowest price in the market. This in-demand module features a ceramic or chrome-plated invincible anilox roller, pivotal servo-motor-driven system, and precision web guide, ensuring flawless coating from 250 microns. With easy-access maintenance, advanced doctor blade systems, and compatibility with IR, hot air, and UV drying, its engineered for unbeatable performance on film, paper, foil, and flexible packaging. Safety, reliability, and outstanding resultsdelivered.

Versatile Application & User Adoption

The ANILOX COATER MODULE utilizes a cutting-edge chambered doctor blade system, delivering precise coatings for a variety of industries. Used by label converters, packaging manufacturers, and print professionals, this module is pivotal for applying uniform coatings on film, paper, foil, and labels. Its invincible operation, combined with a computerized PLC interface, makes it the preferred choice for both high-volume and specialty flexible packaging applications, ensuring repeatable, consistent quality every run.

Certifications, Export Strength & Delivery Timeline

Tested to meet stringent international quality certifications, the ANILOX COATER MODULE is a trusted product in Germany and leading export markets. Sale price offers are secured upon receipt of a purchase order, with prompt handover and installation support as standard. Delivery timelines are tailored per customer specification, ensuring rapid, reliable fulfillment so you can commence production swiftly and cost-effectively with your new state-of-the-art coating solution.

Versatile Application & User Adoption

The ANILOX COATER MODULE utilizes a cutting-edge chambered doctor blade system, delivering precise coatings for a variety of industries. Used by label converters, packaging manufacturers, and print professionals, this module is pivotal for applying uniform coatings on film, paper, foil, and labels. Its invincible operation, combined with a computerized PLC interface, makes it the preferred choice for both high-volume and specialty flexible packaging applications, ensuring repeatable, consistent quality every run.

Certifications, Export Strength & Delivery Timeline

Tested to meet stringent international quality certifications, the ANILOX COATER MODULE is a trusted product in Germany and leading export markets. Sale price offers are secured upon receipt of a purchase order, with prompt handover and installation support as standard. Delivery timelines are tailored per customer specification, ensuring rapid, reliable fulfillment so you can commence production swiftly and cost-effectively with your new state-of-the-art coating solution.

FAQs of ANILOX COATER MODULE:

Q: How does the ANILOX COATER MODULE ensure precision in coating applications?

A: The module features a precision web guide system and servo motor-driven mechanics, guaranteeing accurate, consistent coating thickness adjustable from 2 to 50 microns for optimal quality across various substrates.Q: What types of materials can the ANILOX COATER MODULE handle?

A: Built for versatility, the ANILOX COATER MODULE efficiently coats film, paper, foil, labels, and flexible packaging, making it suitable for diverse industrial and commercial applications.Q: When is onsite support provided for installation and maintenance?

A: Onsite support is made available upon delivery and as needed throughout the modules operation, ensuring seamless installation and reliable maintenance whenever required.Q: Where is the ANILOX COATER MODULE primarily exported?

A: This advanced coating module is predominantly exported to Germany and other key international markets, meeting high quality and safety standards demanded worldwide.Q: What safety measures are incorporated in the ANILOX COATER MODULE?

A: Safety is paramount, featuring overload protection, emergency stop functions, and a low noise level below 80 dB, ensuring operator well-being during usage.Q: How does the computerized PLC control system benefit users?

A: The PLC-controlled system streamlines operation, allows programmable settings, and provides precise color managementdelivering repeatable, high-quality results with minimal manual intervention.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in UV LED for Offset Printing Category

UV LED

Minimum Order Quantity : 10

Automatic Grade : Automatic

Computerized : Yes

Control System : Human Machine Interface

Ink Type : Other

Warranty : 40000 HOURS

UV LED For Offset Printing

Automatic Grade : Automatic

Computerized : Yes

Control System : PLC Control

Ink Type : UV Curing Ink

|

PRECISION MACHINES & AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry