Hot Foil Cutting Attachment

Hot Foil Cutting Attachment Specification

- Product Type

- Foil cutting attachment

- General Use

- Foil stamping and cutting in print finishing applications

- Type

- Hot Foil Cutting Attachment

- Capacity

- High yield, designed for industrial and commercial use

- Weight (kg)

- Approx. 10 kg

- Computerized

- No

- Automatic

- No

- Stamping Plate Size

- 150 mm x 150 mm

- Stamping Power

- Mechanical

- Stamping Speed

- Variable, up to 1000 operations/hour

- Stamping Temperature

- Adjustable (80C 150C)

- Power Consumption

- 500 W

- Plate Type

- Metal heating plate

- Working Temperature

- 80C to 150C

- Heating Power

- 500 W

- Voltage

- 220 V AC / 50 Hz

- Dimension (L*W*H)

- 250 mm x 200 mm x 180 mm

- Color

- Metallic (Silver/Grey)

About Hot Foil Cutting Attachment

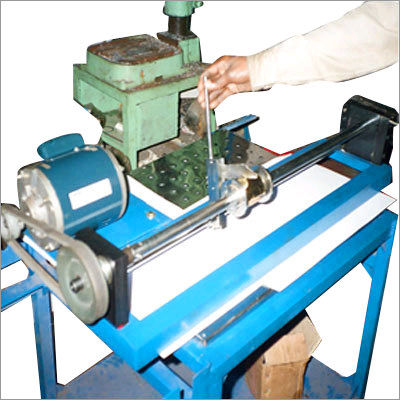

Hot Foil Cutting Attachment

We are offering a high quality gamut of Hot Foil Cutting Attachment to our clients. These are basically used in packaging industries for carrying out enhanced cutting, creasing and embossing of materials. For the convenience of our clients, we make available all these Hot Foil Cutting Attachments in single, double and triple steps. There is an intelligent mechanism of electric heating and temperature control devices to control the process at each step. Our clients cam avail from us this cutting attachment at the most moderate price.

Efficient Print Finishing, Every Time

Engineered for precision and consistency, the Hot Foil Cutting Attachment enhances print finishing by delivering sharp and accurate foil stamping and cutting. Its mechanical operation and high-speed capabilities support large production runs, making it indispensable for commercial and industrial users focused on quality and productivity.

Adjustable Heating and Reliable Performance

With an adjustable working temperature range from 80C to 150C, this attachment accommodates various foil types and substrates. The sturdy metal heating plate and reliable mechanical stamping ensure firm adhesion and crisp cuts, offering control and dependability in demanding environments.

Designed for Practical Integration

Compact dimensions and user-friendly adjustments allow seamless integration into existing print facilities. Operating on standard 220 V AC supply, it provides ease of use and maintains high safety standards, making it a flexible solution for diverse finishing tasks.

FAQs of Hot Foil Cutting Attachment:

Q: How do I operate the Hot Foil Cutting Attachment for optimal foil stamping and cutting?

A: The attachment uses a mechanical action. Start by allowing it to reach your desired stamping temperature (between 80C and 150C), then position your material on the 150 mm x 150 mm plate. Adjust the stamping speed as needed for your workflow, up to 1000 cycles per hour.Q: What materials and foils can be used with this cutting attachment?

A: The device accommodates various foils and substrates typically used in print finishing. The adjustable temperature range enables you to process both metallic and colored foils on paper, cardboard, and similar materials.Q: When should I adjust the stamping temperature?

A: You should modify the temperature based on the type of foil and material being used. Delicate substrates may require lower temperatures, whereas thicker foils and sturdier papers perform best with higher settings up to 150C.Q: Where is this Hot Foil Cutting Attachment manufactured and supplied from?

A: This product is manufactured, exported, and supplied from India, and is available through reputable exporters, manufacturers, service providers, and suppliers specializing in industrial print finishing equipment.Q: What is the process for integrating the attachment with existing print finishing equipment?

A: Installation is straightforward due to its compact design and compatible voltage. Ensure the power supply matches 220 V AC / 50 Hz, securely mount the attachment, and set stamping speed and temperature according to your operational requirements.Q: How can using this Hot Foil Cutting Attachment benefit my business?

A: Employing this attachment facilitates efficient, high-yield foil stamping and cutting, enhancing product presentation, brand value, and customer satisfaction in commercial print output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Foil Stamping Machine Category

Hot Foil Stamping Machine

Heating Power : 2.2 kW

Dimension (L*W*H) : 950 x 700 x 1400 mm

Type : Hot Foil Stamping Machine

Working Temperature : Room temperature to set stamping temperature

Stamping Power : 2 Tons

Product Type : Hot Foil Stamping Equipment

|

PRECISION MACHINES & AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry