Hot Foil Stamping Machine

Hot Foil Stamping Machine Specification

- Product Type

- Hot Foil Stamping Equipment

- General Use

- Foil stamping on paper, cardboard, leather, plastics and similar materials

- Type

- Hot Foil Stamping Machine

- Capacity

- Up to 2000 impressions/day

- Weight (kg)

- Approx. 350 kg

- Computerized

- No

- Automatic

- Semi Automatic

- Stamping Plate Size

- 150 x 200 mm (custom sizes available)

- Stamping Power

- 2 Tons

- Stamping Speed

- Up to 1200 cycles/hour

- Power Consumption

- 2.5 kW

- Plate Type

- Flat metal plate

- Working Temperature

- Room temperature to set stamping temperature

- Heating Power

- 2.2 kW

- Voltage

- 220 V/50 Hz

- Dimension (L*W*H)

- 950 x 700 x 1400 mm

- Feature

- Quick changeover, digital temperature control, pressure adjustment feature

- Color

- Blue & Metallic Grey

About Hot Foil Stamping Machine

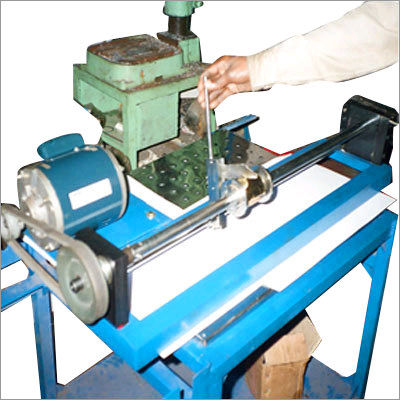

Hot Foil Stamping Machine

We are counted among the leading manufacturers, suppliers and exporters for Hot Foil Stamping Machine. This pneumatic driven stamping machine is basically used in textile industries for printing as well as for embossing purpose. The Hot Foil Stamping Machine finds wide application in printing on various materials like Paper, Plastic, Cloth, Leather and Fiber etc. Our machines have been manufactured wisely so that it can operate on a temperature range of 0 to 200 Celsius.

Further Details :

Working:-

It is a semi automatic machine as you have to Place and Remove the job from the machine platen, the machine cycle starts , when we actuate the foot switch, The stamping slide comes down to stamp according to the preset time in the timer and foil moves instantly after the stamping according to the preset time in the foil timer.

Specifications/features and requirements of the machine:-

1) Compressor required 10 cfm, 3 hp, double cylinder

2) Switching load of Heater 2kw- flat, plate type

3) Working temp can be varied from 0 to 200 Celsius

4) Size of the stamping slide 9, other sizes available as per requirement

5) Working pressure 6 bar

6) Rewinding of foil motorized through 0.25 hp dc motor.

7) Digital controller for temperature with display

8) Easy digital delay settings for both foil and stamping slide.

9) Multicolour printing is possible upto 3 or 4 colors in single cycle

10) Embossing is possible through reverse block

11) Can be easily customized to print on uneven surface(profile)

12) Floor area required 4ft x 3ft for comfortable working of machineEfficient Semi-Automatic Operation

Experience seamless productivity with semi-automatic functioning, allowing operators to achieve up to 1200 cycles per hour. The quick changeover and user-friendly design minimizes downtime, offering a reliable solution for businesses needing consistent, high-quality stamping.

Versatile Material Compatibility

This machine adapts easily for use on a wide range of materials including paper, cardboard, leather, and plastics. The 150 x 200 mm stamping plate accommodates various project sizes, with custom plate options available to suit unique requirements.

Advanced Features for Precision

Benefit from digital temperature control and pressure adjustment features that ensure precise foil transfer. The robust build supports consistent results, while its 2-ton stamping power ensures sharp, clean impressions every time.

FAQs of Hot Foil Stamping Machine:

Q: How does the Hot Foil Stamping Machine operate without computerization?

A: This machine functions via manual and semi-automatic controls, using digital temperature adjustment and mechanical pressure settings. It ensures precision stamping without the need for computerized systems, making it easy to operate and maintain.Q: What materials can be stamped using this machine?

A: The machine is engineered to handle paper, cardboard, leather, plastics, and similar materials. Its versatility enables it to tackle diverse stamping projects across different industries.Q: When should the stamping temperature be set, and what range is recommended?

A: Set the stamping temperature before beginning the process, with adjustments based on material type and foil specifications. The machine operates from room temperature up to the required stamping temperature for optimal results.Q: Where can this Hot Foil Stamping Machine be installed?

A: With compact dimensions of 950 x 700 x 1400 mm, the machine fits comfortably in workshops, print shops, and medium-size production facilities. It requires access to a 220 V/50 Hz power supply.Q: What is the process for changing the stamping plate size?

A: Changing the stamping plate is simple due to the quick changeover feature. Custom-sized plates can be purchased to accommodate different project requirements, ensuring flexibility and efficiency.Q: How is the machines pressure adjusted for different materials?

A: Pressure can be manually adjusted using built-in controls, allowing operators to tailor the stamping force according to the thickness and hardness of the chosen material. This ensures crisp and clear foil impressions each time.Q: What are the benefits of using this Hot Foil Stamping Machine for production?

A: The machine offers high capacity, consistent quality, and reduced downtime. Its semi-automatic function, customizable settings, and robust performance make it ideal for manufacturers seeking reliability and versatility in foil stamping.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Foil Stamping Machine Category

Hot Foil Cutting Attachment

Voltage : 220 V AC / 50 Hz

Computerized : No

Stamping Power : Mechanical

Product Type : Foil cutting attachment

Heating Power : 500 W

Power Consumption : 500 W

|

PRECISION MACHINES & AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry