UV Curing Machine

UV Curing Machine Specification

- Noise Level

- <75 dB

- Control System

- Digital/PLC based

- Cooling System

- Air Cooled

- Features

- Energy efficient, Fast curing, Compact design

- Lubricating System

- Manual

- Accuracy

- High Precision Curing

- Motor Power

- 0.5 HP

- Connectivity Options

- None

- Frame Type

- Heavy Duty Mild Steel

- Machine Type

- UV Curing

- Power Rating

- 2200 W

- Drive

- Belt Drive

- Frequency

- 50 Hz

- Voltage

- 220 V

- Product Type

- UV Curing Machine

- Technology

- UV Curing

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 2.2 kW

- Pressure

- Atmospheric

- Surface Treatment

- Polished

- Dimension (L*W*H)

- 1900 mm x 700 mm x 1600 mm

- Weight (kg)

- 300 kg

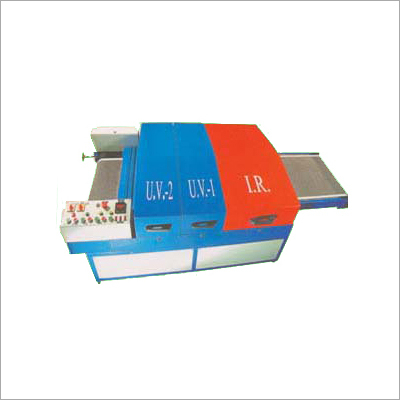

- Color

- Blue & White

- Usage & Applications

- Printing, Coating, Adhesive curing

About UV Curing Machine

U.V. Curing Machine

Owing to our expertise in this domain, we are recognized as the best manufacturers and exporters of U.V. Curing Machine. We have employed the most advanced technology in designing of these curing machines. Our offered U.V. Curing Machines find wide application in the field of the graphic arts for the polymerization of inks and varnishes with ultraviolet radiation. We have employed all the features in this machine to enhance its efficiency. We make available all these machines to our clients at affordable price.

Sophisticated UV Curing Technology

Engineered with advanced UV curing capabilities, this machine achieves rapid and uniform exposure for flawless results in printing, coating, and adhesive applications. The technology enhances productivity by significantly reducing drying times and improving surface quality, making it a preferred choice for modern manufacturing environments.

Designed for Efficiency and Precision

Equipped with a digital/PLC-based control system, the UV Curing Machine maintains high-precision curing with energy-efficient performance. Its automatic operation, air-cooled mechanism, and manual lubrication ensure smooth, consistent functioning with minimal maintenance, suitable for professional and industrial settings.

FAQs of UV Curing Machine:

Q: How does the UV Curing Machine enhance the printing and coating process?

A: The machine utilizes advanced UV technology to rapidly cure inks, coatings, and adhesives, resulting in increased efficiency, superior finish quality, and reduced production timesmaking it ideal for high-volume printing and coating applications.Q: What types of applications is this UV Curing Machine suitable for?

A: This equipment is specifically designed for use in printing processes, surface coating treatments, and adhesive curing, supporting various industrial sectors requiring quick, reliable, and high-precision results.Q: When should the UV Curing Machine be operated for optimal performance?

A: For best results, the machine should be operated during regular production hours with stable input voltage (220 V, 50 Hz) and in environments that can accommodate its dimensions (1900 mm x 700 mm x 1600 mm) and air cooling requirements.Q: Where can this UV Curing Machine be installed within a production facility?

A: Owing to its compact design and moderate weight (300 kg), the machine can be integrated into existing production lines or standalone setups in printing houses, manufacturing plants, or industrial workshops without requiring special connectivity options.Q: What is the curing process involved in this machine?

A: The curing process works by emitting UV light to cure or dry inks, coatings, or adhesives applied to substrates as they pass through the belt-driven system, ensuring a consistent and high-quality finish efficiently.Q: How does the air-cooled system benefit machine operation?

A: The air cooling mechanism maintains optimal operating temperatures, preventing overheating and ensuring consistent curing quality, while also reducing maintenance needs compared to liquid-cooled systems.Q: What are the key benefits of choosing this UV Curing Machine?

A: Users benefit from fast curing speeds, energy-efficient operation, high precision, reduced noise (<75 dB), and a heavy-duty yet compact designideal for manufacturers, exporters, and service providers looking for reliability and consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in U.V. Curing Machine Category

UV Curing System

Cooling System : Air Cooled

Usage & Applications : Printing, coating, adhesives, inks, and electronic parts

Noise Level : <70 dB

Voltage : 220 V

Machine Type : UV Conveyor Curing

Frame Type : Rigid Steel Frame

U V Curing Dryer for Offset Machine

Cooling System : Air Cooling

Usage & Applications : Industrial

Noise Level : low db

Voltage : 220/ 415 Volt(v)

Machine Type : Offset Machine

Frame Type : Metal Frame

|

PRECISION MACHINES & AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry