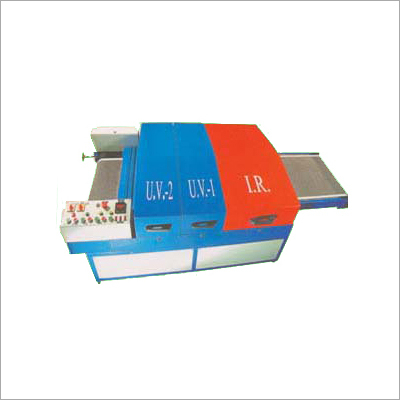

UV Curing System

UV Curing System Specification

- Motor Power

- 0.37 kW

- WorkingSpeed

- 0.5 10 m/min

- Production Capacity

- 200 pieces/hour

- Cooling System

- Air Cooled

- Accuracy

- 1 mm

- Drive

- Chain Drive

- Connectivity Options

- Manual Controls

- Operating Temperature

- 10C to 45C

- Machine Type

- UV Conveyor Curing

- Noise Level

- <70 dB

- Control System

- Digital PLC Based

- Voltage

- 220 V

- Power Rating

- 2.5 kW

- Frame Type

- Rigid Steel Frame

- Product Type

- UV Curing System

- Technology

- Ultraviolet (UV) Curing

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 2 kW

- Pressure

- Atmospheric

- Surface Treatment

- UV Cured

- Dimension (L*W*H)

- 1200 x 700 x 1200 mm

- Weight (kg)

- 150 kg

- Color

- Blue & White

- Usage & Applications

- Printing, coating, adhesives, inks, and electronic parts

About UV Curing System

UV Curing System

Available with us is a wide range of impeccable quality UV Curing Systems. All these systems are manufactured by us using latest technology. Widely used in various applications, our UV Curing Systems are available in varied specifications as per the requirements of our clients. An added feature of the machine is that it can be attached to offset machines as off line coaters, attached to screen printing machines. Our clients can avail from us these high end quality curing systems at affordable price.

Features:

- Curing conveyor with turning fixtures

- Low noise during operation

- Equipped with exquisite cooling system

- Less maintenance cost

| Feature | Economical Model | Advance model |

| Rolling system | Trolley based | Trolley based |

| UV Curing quartz tubes | Albatross | Albatross |

| Lifters for UV Hood in case of emergency | Manual lifters | Pneumatic lifters(Automatic lifting) |

| Paper stacking at conveyor end | Manual | Manual |

| Modes of UV lamps | Half and Full Mode | Half, Full and Standby Mode |

| Speed of conveyor | Variable through VFD | Variable through VFD |

| Suction Blower For sheet and Fumes | 1 HP 2800 RPM | 2 HP 2800 RPM |

| Suction Blower For UV lamps | NA | 1 HP 2800 RPM |

| Isolation Transformer for UV lamp | 12 KW for each lamp | 12 KW for each lamp |

| Additional Features | 1. Safety of uv lamps against over heat by digitally controlled RTD i/p temp controller | |

| 2. If temperature rises to a pre-set value then it will automatically turn off the system and lifters will lift the hoods | ||

Advanced UV Curing Technology

Harnessing ultraviolet light, this system rapidly cures inks, coatings, and adhesives with unmatched consistency. The automated conveyor ensures even exposure across materials up to 600 mm wide, making it ideal for high-volume, precision applications. Featuring digital PLC control, it delivers optimal results for diverse industrial needs.

Enhanced Safety and Maintenance Access

Operator safety is prioritized with built-in emergency stop and overheat protection. The top-hinged cover allows for quick, uncomplicated servicing, minimizing downtime. Combined with a sturdy steel frame and ergonomic design, this UV curing machine delivers dependable operation even in demanding production environments.

FAQs of UV Curing System:

Q: How does the UV curing process work in this system?

A: The UV curing system uses two high-intensity ultraviolet lamps to initiate a photochemical reaction that instantly hardens or dries inks, coatings, and adhesives as materials pass through the curing area via a conveyor, ensuring rapid and even curing.Q: What maintenance procedures are recommended for the UV curing unit?

A: Routine maintenance includes inspecting and cleaning lamp surfaces, checking the axial blower fans for dust, and ensuring the top-hinged cover is securely fastened after any service. The design provides easy access for swift servicing, minimizing production downtime.Q: When should the UV lamps be replaced?

A: The UV lamps are rated for a lifespan of up to 8,000 hours. It is recommended to monitor lamp intensity and replace the lamps once curing efficiency declines or the rated hours are approached, to maintain optimal curing performance.Q: Where is the ideal installation location for this UV curing machine?

A: The machine is designed as a floor-standing unit with a compact footprint, ideally placed in well-ventilated production areas. It operates safely at atmospheric pressure and within temperatures of 10C to 45C, making it adaptable to most industrial environments.Q: What types of materials and applications benefit most from this UV curing conveyor?

A: This system is suitable for curing a variety of substrates in printing, coatings, adhesives, inks, and electronics manufacturing, offering fast and uniform surface treatment while enhancing product durability and throughput.Q: How does the control system enhance operational efficiency?

A: The digital PLC-based control system delivers precise regulation of curing parameters and conveyor speed, facilitating stable, reproducible operation from 0.5 to 10 m/min and accuracy within 1 mm for every production cycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in U.V. Curing Machine Category

UV Curing Machine

Minimum Order Quantity : 1 Piece

Features : Energy efficient, Fast curing, Compact design

Frame Type : Heavy Duty Mild Steel

Voltage : 220 V

Noise Level : <75 dB

Machine Type : UV Curing

U V Curing Dryer for Offset Machine

Features : Heavy Duty

Frame Type : Metal Frame

Voltage : 220/ 415 Volt(v)

Noise Level : low db

Machine Type : Offset Machine

|

PRECISION MACHINES & AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry